- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

Why Diesel Generator Sets Must Use High-Efficiency Air Filters

1. Introduction: Clean Air, Stable Power

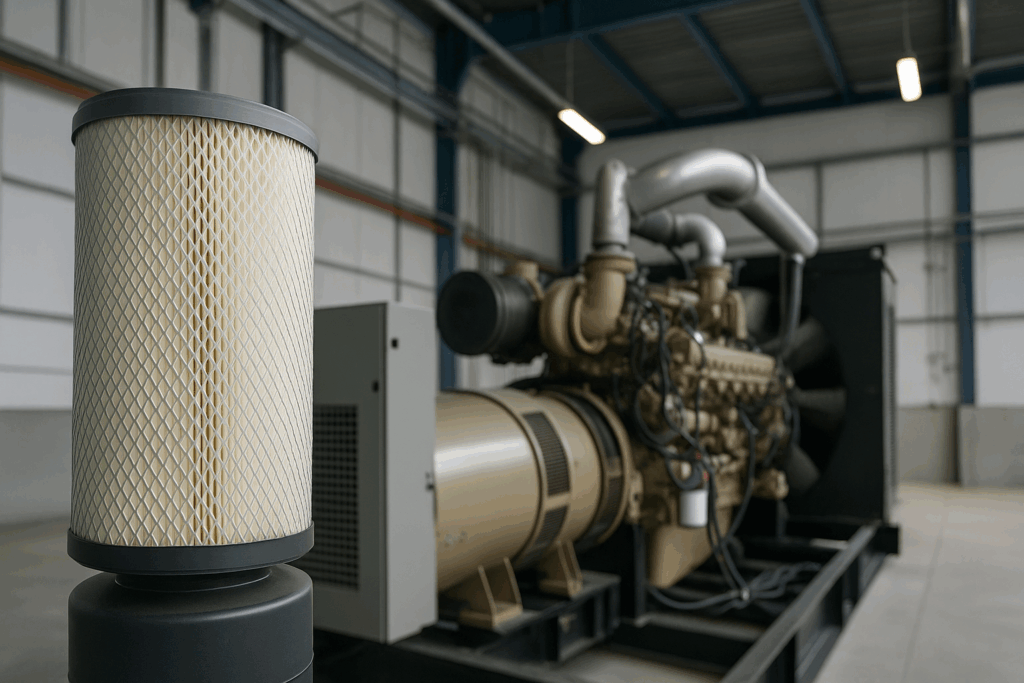

In critical environments such as hospitals, data centers, factories or mining sites, diesel generator sets are relied on to provide uninterrupted and reliable power. But behind this reliability lies an often overlooked but important component – the air filter.

High-efficiency air filtration is not optional in power stations, but a must. Without good air filtration, the generator set will have black smoke, can not carry load and other faults.

2. Why Diesel Generators Need Clean Air Filters

The diesel engines used in generator sets require clean air to operate efficiently. However, generator sets are often in dusty, humid or industrial environments. Our common air pollutants include dust and sand, pollen, fiber, insects, moisture and salt. Salt is common in coastal cities and industrial smoke and exhaust in cities. If the air does not pass through the air filter, these particles will enter the engine combustion chamber, which may wear the piston and clog the injector, which will greatly shorten the engine life.

Roles of High-Quality Generator Air Filters in Engines

✅ 1.Protect the engine from wear and tear

The air filter blocks dust from entering the engine and prevents wear and tear on engine parts. In daily use, a speck of dust may cause micro-wear on the cylinder wall, and dust entering the cylinder liner after thousands of hours of work will cause early engine failure.

✅ 2. Ensure stable power output

Contaminated air will destroy the engine’s combustion efficiency, causing speed fluctuations, that is, it cannot be accelerated, uneven power output, and if it is during peak load, it will cause the generator to trip.

✅ 3. Optimize fuel efficiency

A dirty air filter will reduce air flow, forcing the engine to burn more diesel at the same output power. Filtered air through the air filter helps maintain the best oil-gas mixture and reduces fuel consumption.

✅ 4Reduce downtime and maintenance

High-quality air filters can ensure long maintenance intervals and blockage risks for the generator set, which can minimize unexpected downtime.

3. Real Case: The Cost Of Poor Filtering Effect

A 1000 KVA Cummins generator runs 12 hours a day in a dusty mining area. Because the mine owner did not pay attention to the air filter, he bought some heavy-duty filters on the market and used them on the generator set. After the generator set ran for 6 months, the injector failed and stopped unexpectedly twice, which forced it to shut down for maintenance. During the maintenance process, it was not only necessary to replace the air filter, but also the injector, oil filter, diesel filter, and check the oil and antifreeze.

After many communications with us, the mine owner chose our high-efficiency filter, and the normal operation time of the generator set reached 99.9%, the maintenance interval became longer, and the fuel economy was better.

4. Why Universal Filter Elements Do Not Work In Power Generation?

Many people think that as long as the air filter is of the right size and installed on the generator set, it can work normally. However, in generator applications, this logic is wrong: the filter area of the general filter element does not meet the requirements of the unit and is easy to clog, the sealing effect is poor, dust easily bypasses the air filter and enters the engine, and many papers are untreated and easily fail in humid or high temperature environments.

Generators need special high-efficiency filters, especially generators that run continuously for 24 hours.

When choosing a diesel generator air filter, we should pay attention to choosing air filters with high dust holding capacity, multi-layer or nanofiber, oil cloth, HV high-efficiency filter paper filter media, paper treated to cope with moisture and corrosion, matching with original accessories, and can be applied to CAT, Cummins, Perkins, Volvo Penta, MTU, John Deere, Land Rover, BMW and other brands DieselAirFiltration.com, we focus on high-performance air filters for generators of various sizes and brands.

Conclusion:Protect The Generator Filter

For diesel generators, clean air is the first line of defense for the fuel system. Efficient air filters are more than just maintenance; they’re a critical component to power reliability.

Whether your generator sets power hospitals, oil rigs, or industrial facilities, don’t let poor air filters cause downtime.

Invest in quality air filtration today—because when power is critical, clean air is power.

Comments

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Learn how to select and replace air filters for CAT 3500 series diesel and gas gensets to protect engines, reduce downtime, and ensure reliable long-term operation.

Why Do Diesel Engines Need Air Filter

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00