- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

The Crucial Function of Air Filtering in the Marine Environment

Reliable air filtration is necessary for functional dependability, equipment life expectancy, and the health and benefit of crew and passengers. Inadequate filtering triggers sped up wear, reduced effectiveness, increased upkeep, and health dangers. Specialized marine filters are needed to handle unique contaminants like sub-micron salt crystals.

What Are Marine Air Filters? Types, Materials, and Function

Marine air filters are specialized aspects produced to eliminate pollutants from air on vessels. Unlike standard filters, they are engineered to withstand harsh marine conditions (salt, dampness, vibration). Secret applications consist of Engine Consumption Systems (securing engines from salt/particulates), HVAC Systems (ensuring clean air in occupied areas), and Specialized Systems (e.g., compressed air).

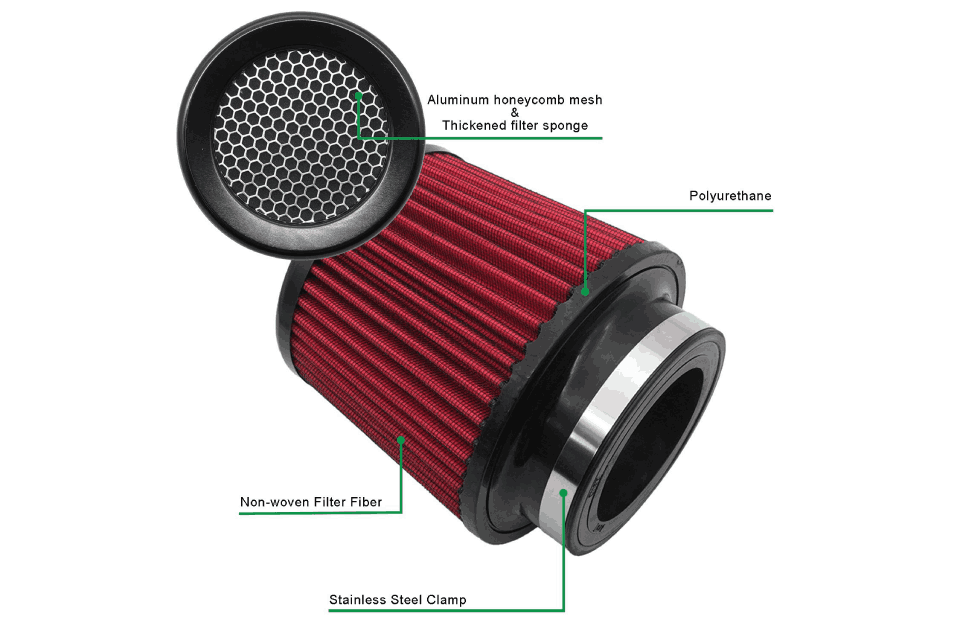

Products are chosen for strength and degeneration resistance, consisting of synthetic fibers, stainless-steel, and triggered carbon. Capture systems include mechanical purification, impaction, interception, diffusion, electrostatic tourist attraction, coalescence (for liquids), and adsorption (for gases). Multi-stage filtering regularly utilizes pre-filters to protect final filters.

Why Marine Filtration is Essential: Challenges and Repercussions

The marine environment’s obstacles require robust filtering:

Salt Spray & Aerosols: Highly corrosive, causing sped up deterioration on parts (engines, electronic gadgets) and fouling filters/heat exchangers.

High Humidity: Increases rust rates and promotes microbial advancement (bacteria, mold) in systems.

Vibration: Can damage filters and properties, and remove taped particles.

Diverse Contaminants: Consists of dust, oil mist, exhaust, and biological representatives.

Consequences of bad filtering are extreme:

Accelerated Devices Wear: Abrasive particles damage engines and equipment.

Increased Upkeep & Downtime: Regular repairs and decreased life span lead to greater expenses and operational disturbance.

Health Threats: Poor air quality impacts crew/passenger health.

Non-Compliance: Failure to meet guidelines (e.g., IMO MARPOL Annex VI) on emissions and air quality.

Applications and Choice Criteria

Marine filters are used in Engine Spaces (consumption, compressed air), Lodging Areas (HEATING AND COOLING), and Control Rooms (securing electronic devices).

Selecting filters needs thinking about:

Application Requirements: Type of pollutants, air flow, appropriate pressure drop.

Effectiveness Standards: MERV or ISO 16890 rankings for particle capture.

Flow Rates & Pressure Drop: Need to handle required air circulation without excessive resistance, which affects system efficiency.

Product Resilience: Resistance to salt, humidity, and rust (e.g., 316L stainless-steel for real estates).

Dust Holding Capacity: Impacts life expectancy.

Size & Setup: Need to fit provided area.

Maintenance & Replacement: Alleviate of service and filter accessibility.

Regulatory Compliance: Fulfilling global and category society standards (e.g., IMO MARPOL).

Life Process Expense (LCC): Including energy use from pressure drop.

Installation, Upkeep, and Keeping Track Of Finest Practices

Efficient filtering counts on appropriate practices

Setup: Follow manufacturer guidelines, assurance proper sealing to prevent bypass, safeguarded setting up versus vibration.

Maintenance: Regular examinations for damage/loading. Screen pressure drop as an essential sign for cleaning/replacement. Adhere to replacement schedules based upon condition or time. Usage genuine or comparable replacements.

Tracking: Differential pressure tracking is essential. Visual assessment and tracking downstream devices performance likewise help. Data logging help proactive upkeep. Predictive maintenance makes use of noticing units and data analytics to enhance schedules.

Performance Assessment and Durability in Service

Efficiency is examined by Performance (particle capture), Pressure Drop (air flow resistance), Dust Holding Capability, and Life Span. Marine conditions considerably impact resilience.

Elements influencing life expectancy

Environmental: Pollutant type/concentration (particularly salt), humidity, temperature level.

Operational: Airflow rate, running hours, upkeep quality.

Filter Characteristics: Media type, structure, effectiveness, housing stability.

Enhancing performance and life consists of suitable system design/sizing, multi-stage filtering, tactical positioning, routine monitoring (condition-based maintenance), using top-notch marine-grade filters, and proactive cleansing.

Advanced Technologies and Regulatory Landscape

Advanced innovations are improving marine filtration:

Smart Filters: Integrated sensors for continuous monitoring (pressure, potentially particle type/loading) making it possible for predictive upkeep.

Advanced Media: Research into products with enhanced efficiency, moisture resistance, and dust capability.

Integrated Systems: Combining different filtration innovations.

Regulations, primarily from the IMO (MARPOL Annex VI), drive developments:

NOx, SOx, PM Emissions: Stricter limitations, especially in Emission Control Areas (ECAs), need efficient engine consumption purification for ideal combustion and compliance.

GHG Reduction: Filtration adds to sustain performance.

Waste Management: Encourages lessening non reusable filters.

Future trends include increased combination with vessel systems, improved sensing unit technology, modular styles, concentrate on circular economy principles, and potentially more stringent indoor air quality requirements.

Conclusion

Ensuring Reliability and Safety Through Effective Filtration

Reliable air filtration is important in the tough marine environment for operational dependability, equipment longevity, and health/safety. Specialized filters are needed to combat salt, humidity, and pollutants. Appropriate choice based on application and standards (MERV/ISO 16890), thorough setup, maintenance (particularly pressure drop tracking), and leveraging advanced innovations are essential. Driven by progressing regulations and technological development, marine air filtration is crucial for safe, effective, and ecologically responsible maritime operations.

Comments

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

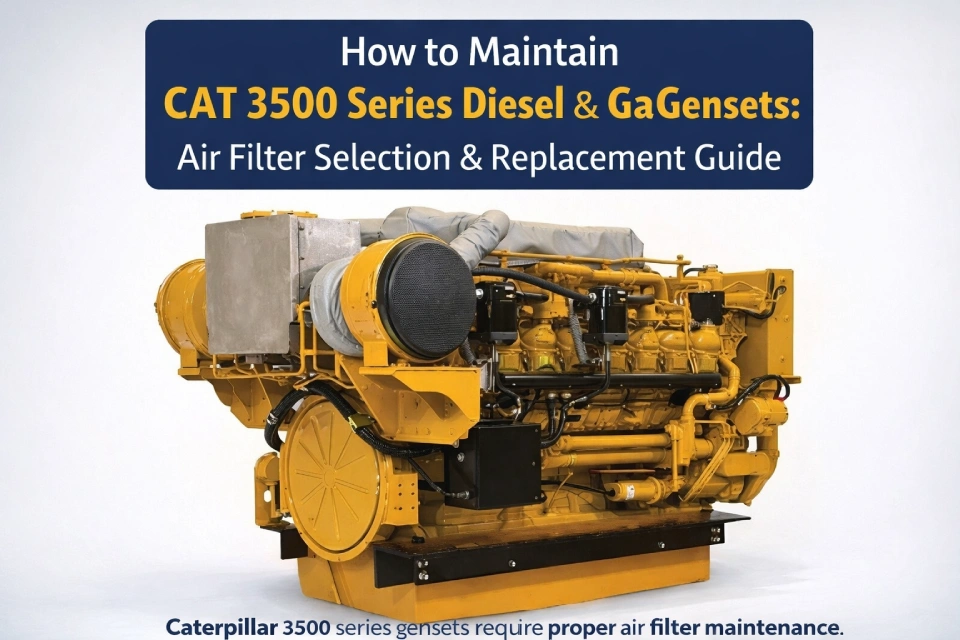

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Learn how to select and replace air filters for CAT 3500 series diesel and gas gensets to protect engines, reduce downtime, and ensure reliable long-term operation.

Why Do Diesel Engines Need Air Filter

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00