- +86 131 5315 0933

- [email protected]

- Промышленный парк Цзинань Фусин

CAT 3512/3516 Three-Filter Set: 1R0726, 1R0756, 8N6309 — Stable Protection for Diesel & Gas Generators

If you operate a CAT 3512 or 3516 engine—whether it’s a diesel genset on a construction site or a gas generator running 24/7—you already know one thing: these large engines rely heavily on a stable, well-matched filter set.

And that set usually comes down to three familiar part numbers:

1R0726 – Oil Filter

1R0756 – Fuel Filter (Primary)

8N6309 – Air Filter

They look simple, but together they decide how long a 3516 can run without unexpected downtime. Below is a practical, factory-level view of how this filter trio works, why they must be replaced as a set, and how we make them at Bowei for long, steady service hours.

To keep a CAT 3512 or 3516 engine running smoothly—whether diesel or gas—the filter trio 1R0726 (oil), 1R0756 (fuel), and 8N6309 (air) does more work than most people notice.

If you’re new to generator filtration, our other guide on high-efficiency diesel generator air filters explains why airflow stability matters so much.

Why the 3512/3516 Needs These Three Filters Working Together

CAT built the 3512 and 3516 as heavy-duty workhorses. But in real operation—mining sites, industrial plants, marine units, or power stations—the engine will only stay stable if:

the oil stays clean,

the fuel stays clean, and

the intake air stays clean.

So the logic is simple:

If one filter fails, the others immediately suffer.

1R0726 (Oil Filter)

Keeps soot, carbon, and fine wear particles out of the lubrication system.

A small restriction here can quickly lead to bearing wear и oil pressure instability.

1R0756 (Fuel Filter)

Protects the injectors from particles and water.

Diesel engines—especially older 3512B or 3516B units—depend on stable injector pressure.

8N6309 (Air Filter)

Gives the engine clean intake air so combustion stays efficient and the turbocharger stays healthy.

Replacing only one or two of them is like changing one shoe—the engine won’t run at full stability.

Diesel vs. Gas Generator: The Differences Matter

Many suppliers ignore this, but filtration demands are not the same for diesel and gas units.

For Diesel 3512/3516

More soot

Higher metal wear particles

Fuel contamination is common

Oil becomes dirty faster

Diesel engines need stronger filtration and more frequent fuel filter replacement.

For Gas 3512/3516

Combustion is cleaner

Air filter quality becomes far more important

The engine is sensitive to airflow drop

Oil stays cleaner, but oil filter must maintain consistent micron rating

Gas generators depend heavily on stable, unrestricted airflow, which is why 8N6309 plays a bigger role.

We highlight these differences during production because many fleets mix diesel and gas units in the same power plant.

Gas engines make the airflow even more important.

If airflow drops, combustion becomes unstable. We described this behavior in more detail in our article on air filtration in demanding marine and gas environments.

How Bowei Produces These Filters (Real Factory Details)

You asked for real factory elements, so here they are—exactly how we make them.

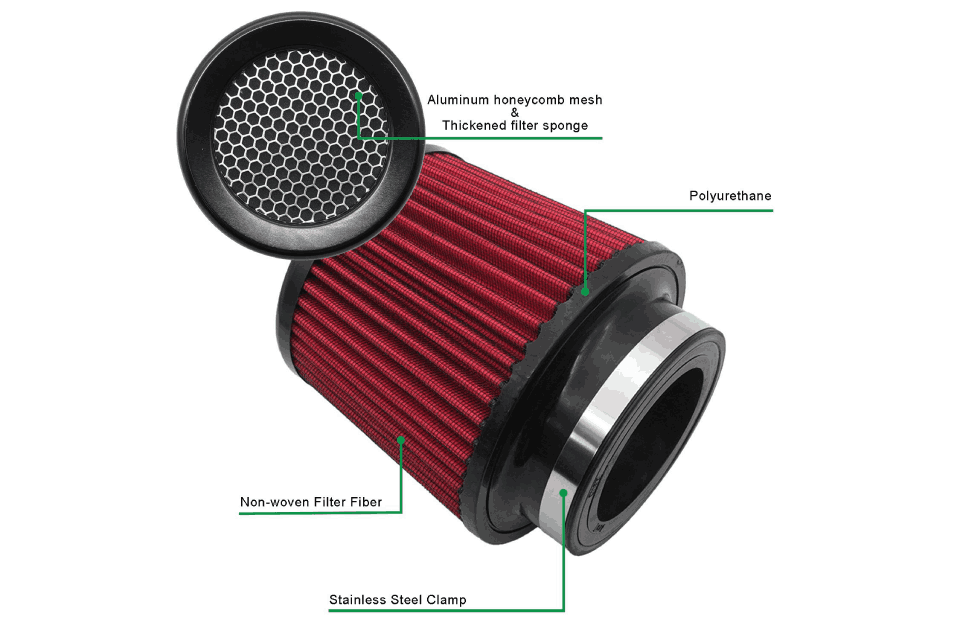

PU Molding That Doesn’t Soften

For 8N6309 we use a controlled PU mixing ratio.

Each batch passes:

hardness test

cure-time check

adhesion test with the metal mesh

Cheap filters often soften after one season.

Ours stay firm because the PU recipe is stable.

HV Filter Paper with Consistent Pleating

The air filter core uses HV composite paper.

Our automatic pleating machine keeps:

pleat depth

pleat distance

pleat count

fully consistent across the entire circumference.

This ensures the airflow doesn’t fluctuate during operation—a key requirement for gas engines.

Strong Metal Mesh + Automatic Welding

The inner mesh is cut and welded by automatic machines.

The weld seam stays uniform, so the paper doesn’t collapse under negative pressure.

100% Manual Visual Check Before Packing

Every 1R0726, 1R0756, and 8N6309 goes through:

glue line inspection

end-cap bonding check

filter paper alignment

sealing ring integrity check

This final step is simple but extremely effective.

It’s why our filters arrive with fewer defects during installation.

Replacement Interval (Realistic, Based on Field Use)

We summarize what most operators follow:

3512 / 3516 Diesel

Oil Filter 1R0726: 250–500 hours

Fuel Filter 1R0756: 250 hours

Air Filter 8N6309: 500–1000 hours depending on dust

3512 / 3516 Gas

Oil Filter 1R0726: 500–1000 hours

Air Filter 8N6309: 1000–2000 hours

Fuel filter may not be needed depending on installation

These are practical numbers—not lab numbers.

Where These Filters Are Commonly Used

You will find them in:

mining power stations

standby generator rooms

drilling platforms

marine propulsion and auxiliary engines

industrial combined-heat-power (CHP) gas plants

Anywhere a CAT 3512/3516 works, this trio works with it.

Why Many Customers Buy the Whole Set from Us

Our customers (Russia, Middle East, Africa) often prefer to order the complete set rather than single filters because:

they want consistent quality

one supplier = easier maintenance planning

less chance of mismatched filters

stable long-term supply for fleets

We prepare bulk orders of these three part numbers regularly in the factory.

If You Use CAT 3512/3516 Units, We Can Support You

Whether you maintain five engines or fifty, we can:

prepare stable long-term supply plans,

provide wholesale pricing for fleets,

support OEM customization,

pack filters by set to reduce installation mistakes.

Электронная почта: [email protected]

WhatsApp: +86-131 535 0933

For fleets using multiple CAT engines, other high-flow filters—like Р636070—follow the same airflow stability principles.

Operators managing mixed fleets often compare CAT and Cummins filtration strategies.

We also published a practical Cummins filter selection guide that many technicians found helpful.

P636070 Air Filter (PA5735 Equivalent): Built for Heavy-Duty Generator and Industrial Applications

A practical guide to the P636070 / PA5735 type disposable air cleaner. We explain its dimensions, airflow range, typical applications, and how Bowei builds an equivalent version for generators and industrial engines using HV filter paper, strong housings, and controlled production.

Зачем дизельным двигателям нужен воздушный фильтр

Дизельные двигатели полагаются на воздушные фильтры, которые обеспечивают их оптимальную производительность и долговечность, предотвращая попадание в систему сгорания загрязняющих частиц, таких как пыль, грязь и другие твердые частицы.

Руководство по быстрому выбору лучшего воздушного фильтра для дизельного двигателя

Для дизельных двигателей, особенно для внедорожной техники, правильный выбор воздушного фильтра имеет большое значение для надежной работы и долговременной защиты двигателя

Какой эффект дают воздушные фильтры для модифицированных автомобилей и мотоциклов?

Роль воздушного фильтра двигателя заключается в фильтрации песка и пыли в воздухе, обеспечении качества воздуха, поступающего в цилиндр

На чем основана конструкция воздушного фильтра двигателя?

Основная задача воздушного фильтра - эффективно предотвращать попадание всех видов пыли во впускную систему двигателя

- +86 131 5315 0933

- [email protected]

- Пн-Сб 07:00-21:00

Теги

Проснувшись однажды утром после беспокойного сна, Грегор Замза обнаружил, что он у себя в постели превратился в страшное насекомое.