- +86 131 5315 0933

- [email protected]

- Промышленный парк Цзинань Фусин

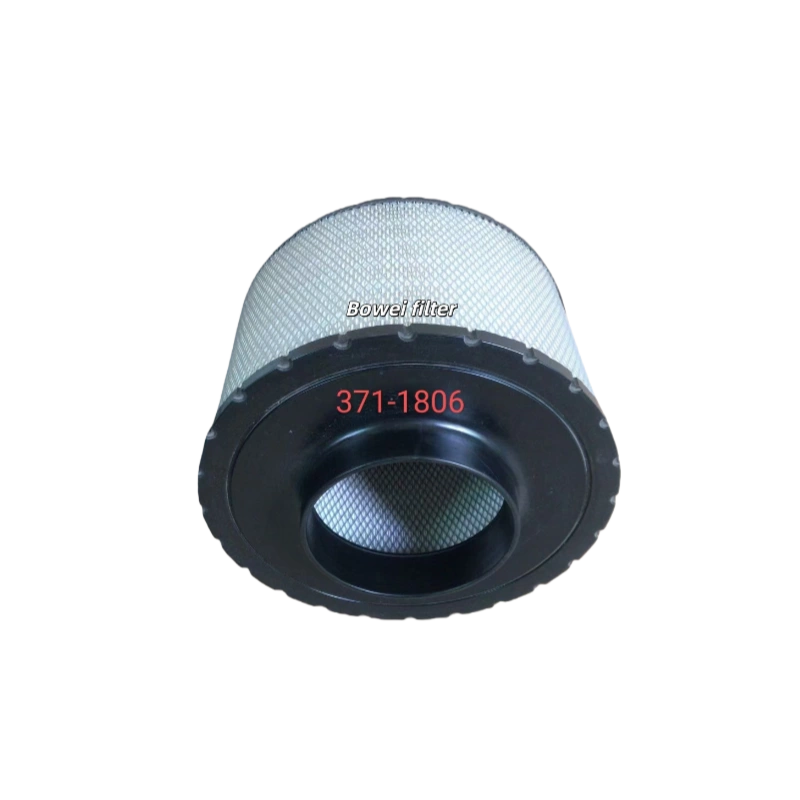

371-1806 Air Filter Replacement for Caterpillar | Cross 10000-57057 / 7C1571

371-1806 Primary Air Filter — Manufactured in Our Bowei Filter Factory

The 371-1806 is one of the large-diameter primary intake filters we manufacture for customers operating Caterpillar generator and industrial engines.

This model uses a PU molded endcap, allowing the filter to be installed directly onto the engine’s intake system without requiring a separate air housing assembly. Many CAT generator engines adopt this direct-mount style to reduce vibration, simplify servicing, and improve sealing consistency.

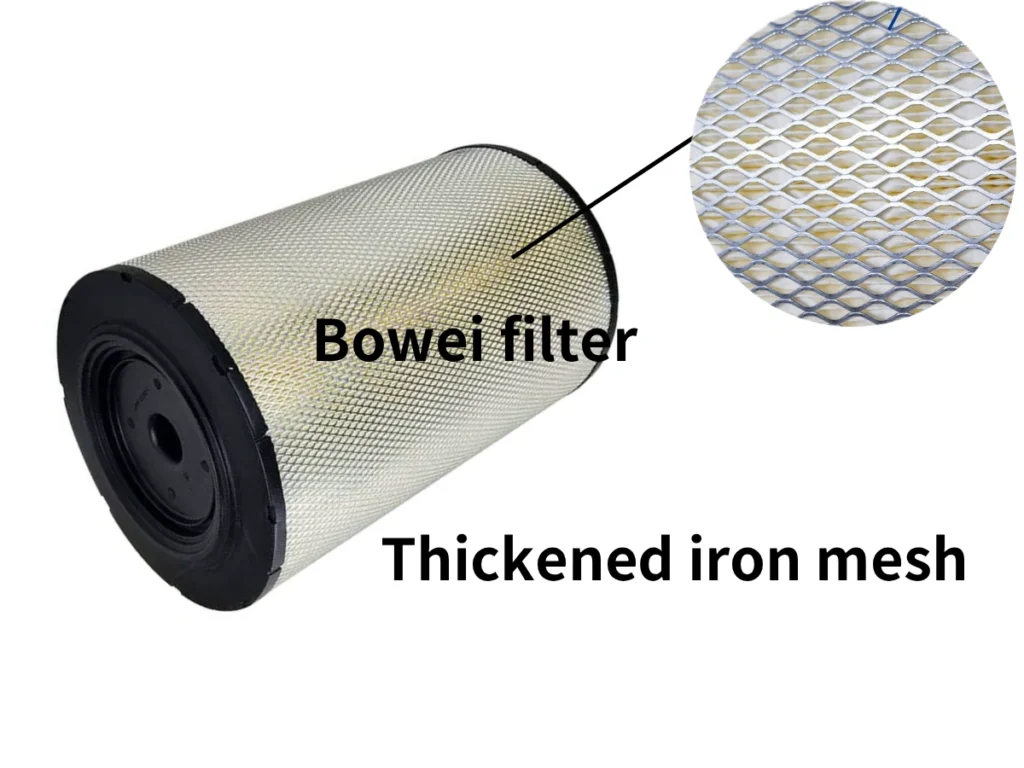

High-Efficiency HV Filter Media

Since this filter is commonly used in CAT 3406B, C13, C15, C18, 3412C and 3512 engines, we build it using imported Высокоэффективная фильтровальная бумага HV. HV media provides excellent dust-holding capacity and stable airflow during long-hour generator operation.

Benefits of HV media for generator sets:

Higher initial filtration efficiency (better turbo protection)

Longer service intervals in dusty environments

More stable pressure drop during long runtime

Better resistance to moisture and pulsating airflow

Before pleating, every batch of HV paper is tested for stiffness and moisture balance. After pleating, our QC team manually inspects pleat spacing and structural integrity.

Overall Height: 236 mm

Внешний диаметр: 318 мм

Внутренний диаметр: 150 мм

All dimensions are verified after PU curing to ensure correct fitment inside CAT intake adaptors.

Совместимые двигатели

The 371-1806 fits a wide range of Caterpillar engines including:

3406B Generator Set

C13

C15 / C15 I6

C18

3412 / 3412C

3512

These engines are often used in generator sets, industrial power units, mining equipment and oilfield sites—environments where filtration reliability is critical.

Номера перекрестных ссылок

10000-57057

7C1571

371-1806 (OEM Equivalent)

Our Bowei Factory’s QC Process

To ensure reliability on high-horsepower CAT generator engines, each filter goes through the following procedures:

PU endcap molded in a single injection process

HV filter media pleated by machine and verified manually

Reinforced mesh checked for tension and deformation resistance

Endcap sealing surface inspected to prevent air leakage

Full measurement check: height, OD, ID

Random ΔP (pressure drop) test at 180 Pa

Cleaning, labeling, bagging, and packing

This level of inspection is what allows our 371-1806 units to perform consistently across global generator fleets.