- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

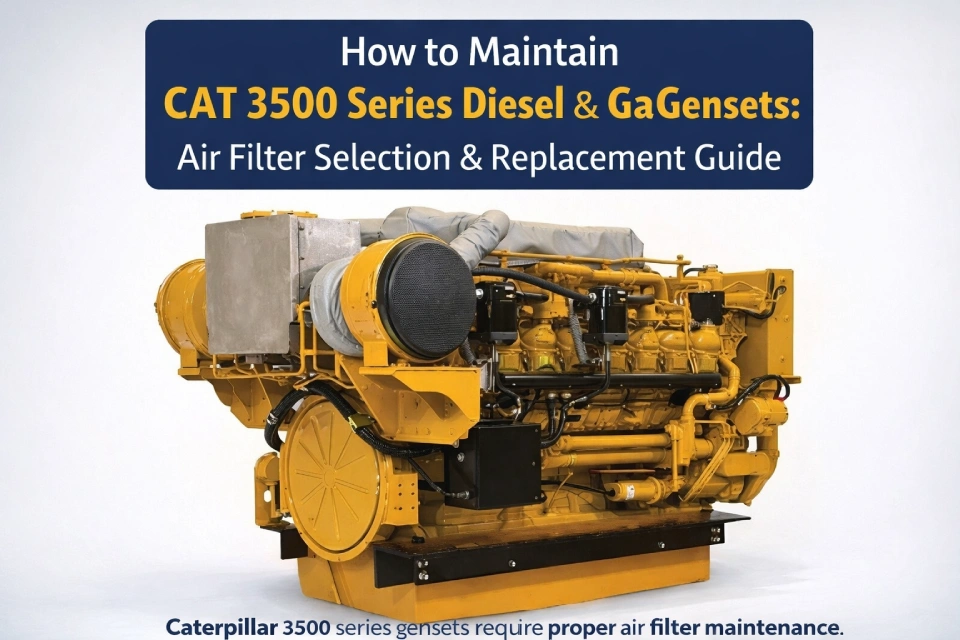

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Large diesel and gas generator sets from the Caterpillar 3500 series are widely used in continuous and standby power applications, including data centers, oil & gas facilities, mining sites, and remote industrial projects.

In these demanding environments, air filtration is one of the most critical maintenance items affecting engine reliability, fuel efficiency, and service life.

This guide explains how to select and replace air filters for CAT 3500 series gensets, and why choosing the right filtration solution matters for long-term operation.

Why Air Filtration Is Critical for CAT 3500 Series Gensets

Engines in the CAT 3500 family—such as 3508, 3512, and 3516—operate with extremely high airflow requirements.

Any unfiltered dust or debris entering the intake system can lead to:

Accelerated wear of pistons, liners, and turbochargers

Reduced combustion efficiency

Increased fuel consumption

Premature engine overhaul

For this reason, proper air filtration is the first line of defense for CAT 3500 series diesel and gas generator sets.

For a full overview of compatible intake filtration options, see our Caterpillar air filters for diesel generator sets.

Common Air Filter Requirements for CAT 3500 Engines

Service teams maintaining CAT 3500 gensets typically look for air filters that meet the following criteria:

High dust-holding capacity to support long service intervals

Stable airflow with low restriction under heavy load

Durable construction, including reinforced metal mesh

Consistent sealing performance to prevent bypass air

These requirements are especially important for generators operating in desert, mining, or high-dust industrial environments.

Recommended Primary Air Filter for CAT 3500 Series Gensets

105-9741 Primary Air Filter – OEM-Compatible Replacement

The 105-9741 primary air filter is widely used on Caterpillar 3508, 3512, and 3516 diesel and gas generator sets.

Designed for high-airflow industrial applications, it provides reliable intake protection under continuous and standby operating conditions.

One of the most commonly used primary air filters for CAT 3500 series generator engines is the 105-9741 air filter.

This model is designed for use on Caterpillar 3508, 3512, and 3516 diesel and gas gensets, providing reliable intake protection for continuous power generation applications.

Key features include:

OEM-compatible fit and dimensions

High-efficiency pleated filter media

Reinforced structure for stable airflow

Suitable for industrial and power generation service conditions

You can view full specifications here:

105-9741 air filter for Caterpillar 3500 series gensets

Single Air Filter vs Complete Filter Set – What Do Service Teams Prefer?

While replacing a single air filter may be sufficient for routine inspections, many generator operators and maintenance contractors prefer to service CAT 3500 engines using complete filter sets.

Why complete filter sets are widely used:

All required filters replaced at the same maintenance interval

Reduced risk of uneven wear across filtration systems

Faster servicing and reduced downtime

Easier inventory and spare parts planning

For scheduled maintenance and overhaul preparation, many operators choose a CAT 3500 complete filter set rather than sourcing individual filters separately.

Replacement Intervals & Maintenance Tips

Actual replacement intervals for CAT 3500 series air filters depend on operating conditions. However, general best practices include:

Inspect air filters regularly in dusty or harsh environments

Monitor air restriction indicators where installed

Replace filters earlier when operating in mining, desert, or construction zones

Always ensure proper sealing after installation

Using OEM-compatible air filters that meet engine airflow and filtration requirements helps maintain stable generator performance and extend engine life.

Conclusion

Proper air filtration plays a vital role in maintaining the performance and durability of Caterpillar 3500 series diesel and gas generator sets.

Selecting the right primary air filter—and choosing complete filter sets for scheduled maintenance—helps operators reduce downtime, control maintenance costs, and protect high-value engines in demanding industrial environments.

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Learn how to select and replace air filters for CAT 3500 series diesel and gas gensets to protect engines, reduce downtime, and ensure reliable long-term operation.

Why Do Diesel Engines Need Air Filter

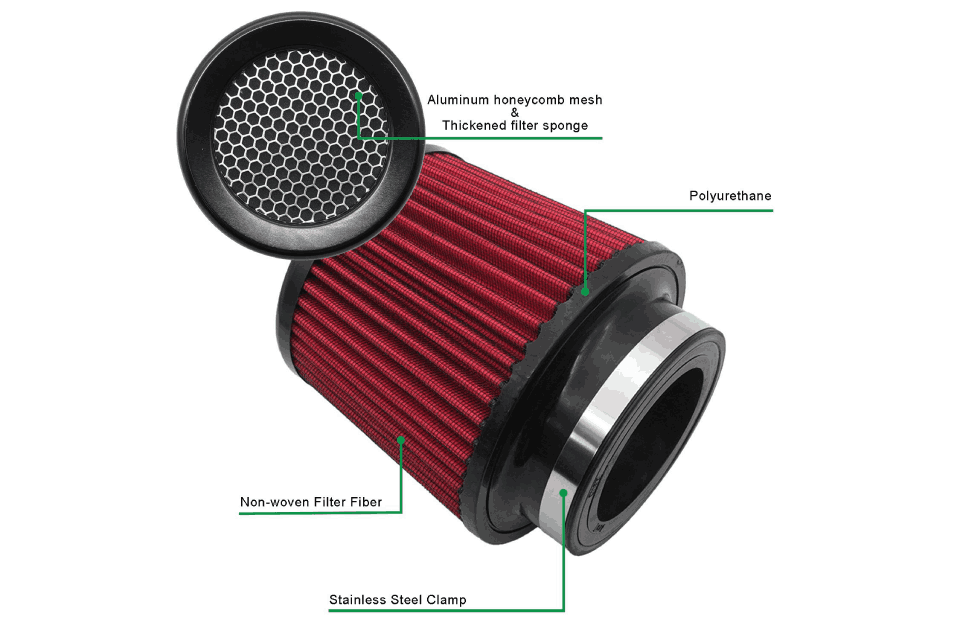

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00

Tags

这是测试文本,单击 “编辑” 按钮更改此文本。