- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

How To Check and Clean Your Generator’s Air Filter

All diesel generators are equipped with air filters to capture dust, sand, debris, and any other airborne impurities that may enter the engine. However, over time, debris can build up and cause engine problems, such as the engine not being able to carry a load or rev or suddenly shutting down. Regularly changing the air filter is an important part of maintaining your generator and will help keep your engine in top condition. This guide will walk you through the process of changing your air filter. See below for a video demonstrating this process

Before you begin, make sure the generator’s engine and muffler are completely cool. Make sure the engine switch and fuel valve are off.

Air filter installation steps

Air filter installation steps

When changing the air filter, we must first

1: Ensure safety and confirm that the engine and muffler of the generator are completely cooled. Turn off the engine switch and fuel valve.

2: Remove the old air filter from the machine. If the air filter has a removable inner core, the inner core must also be removed together. When removing the old air filter nearby, be careful to remove the old air filter to prevent dust or debris from falling into the filter assembly.

3: Clean the filter assembly. Use a clean cloth or appropriate cleaning tools to clean the inside of the air filter assembly to remove residual dust, sand or other debris.

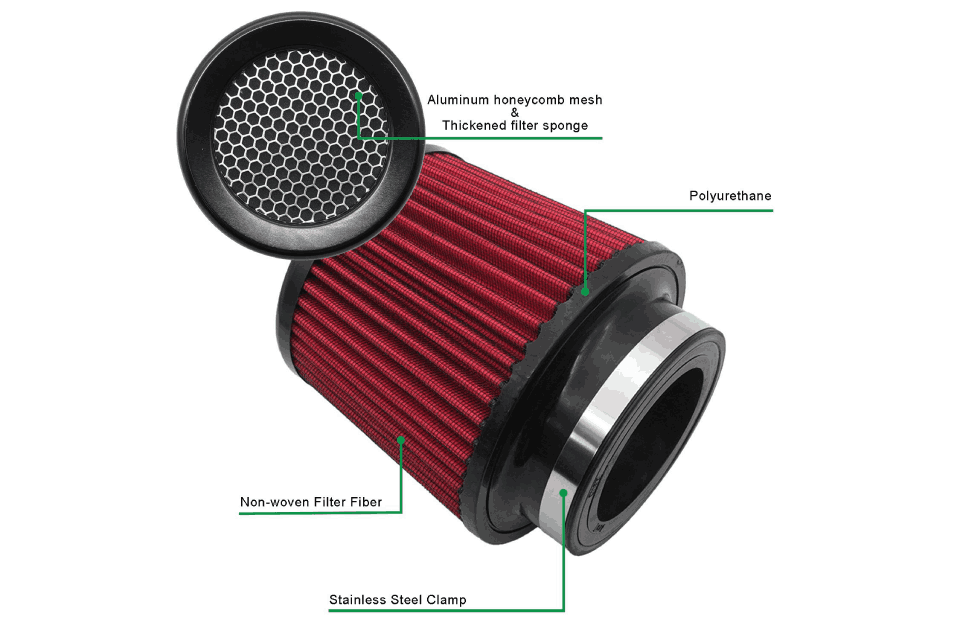

4: Install the new air filter Check the quality of the new air filter to ensure that the filter paper and inner core meet the requirements (high-quality inner core can improve the filtering effect). Install the new air filter correctly into the filter assembly to ensure a good seal.

5: Check and complete

Confirm that the new air filter is installed firmly without looseness or gaps. Close the air filter assembly cover to ensure a seal.

6: Start the generator, check the operating status, and verify whether the new air filter improves power or reduces fuel consumption.

Notes

Replace the air filter regularly to maintain optimal engine performance.

Use high-quality air filters to ensure good filtration and longer service life

Installation steps

Comments

P636070 Air Filter (PA5735 Equivalent): Built for Heavy-Duty Generator and Industrial Applications

A practical guide to the P636070 / PA5735 type disposable air cleaner. We explain its dimensions, airflow range, typical applications, and how Bowei builds an equivalent version for generators and industrial engines using HV filter paper, strong housings, and controlled production.

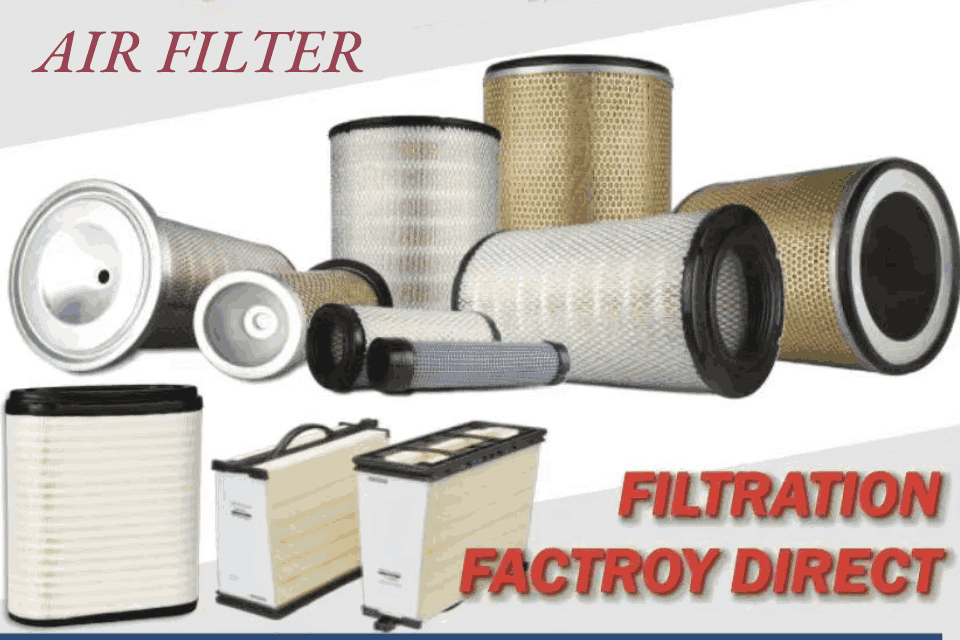

Why Do Diesel Engines Need Air Filter

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00