- +86 131 5315 0933

- [email protected]

- شهرک صنعتی فوشینگ جینان

فیلتر هوا در موتور دیزل چیست؟

فهرست مطالب

مقدمه

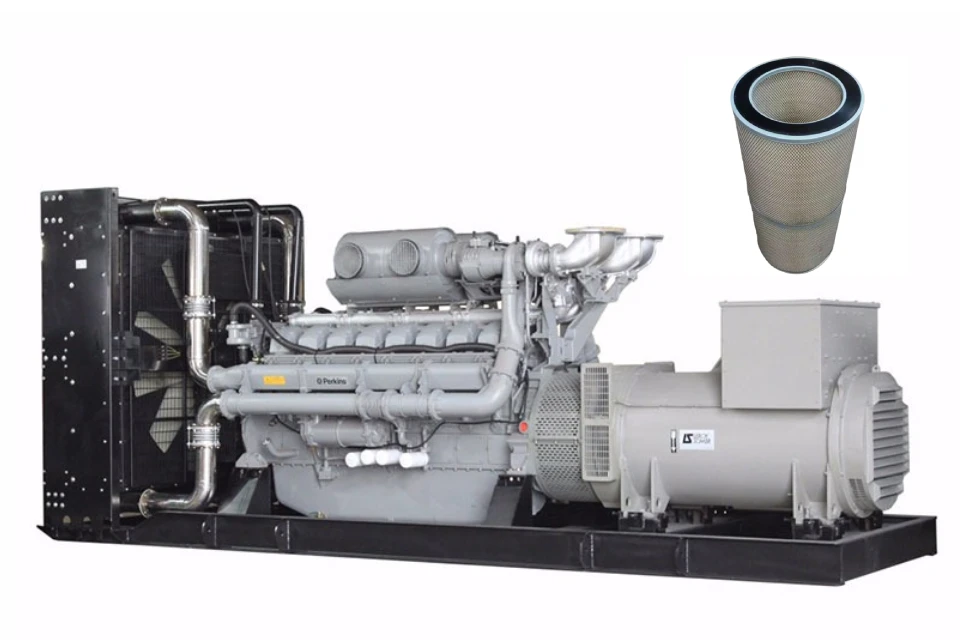

فیلتر هوا نوعی فیلتر است که به آن فیلتر هوا نیز گفته میشود. فیلتر هوا کارتریج، فیلتر هوا، مدل و غیره. این ماده عمدتاً برای تصفیه هوا در لوکوموتیوهای مهندسی، خودروها، لوکوموتیوهای کشاورزی، آزمایشگاهها، اتاقهای عمل استریل و اتاقهای عمل دقیق مختلف استفاده میشود.

عملکرد فیلتر هوا

موتور در حین کار نیاز به استنشاق مقدار زیادی هوا دارد. اگر هوا فیلتر نشود، گرد و غبار معلق در هوا به داخل سیلندر مکیده میشود که باعث تسریع سایش گروه پیستون و سیلندر میشود. ذرات بزرگتر که بین پیستون و سیلندر وارد میشوند، باعث "کشیدگی سیلندر" جدی میشوند که به ویژه در محیطهای کاری خشک و شنی جدی است. فیلتر هوا در جلوی کاربراتور یا لوله ورودی هوا نصب میشود تا گرد و غبار و شن موجود در هوا را فیلتر کند و از ورود هوای کافی و تمیز به سیلندر اطمینان حاصل شود.

طبق اصل فیلترینگ، فیلترهای هوا میتوان آن را به انواع فیلتر، گریز از مرکز، حمام روغن و کامپوزیت تقسیم کرد. فیلترهای هوای رایج مورد استفاده در موتورها عمدتاً شامل فیلترهای هوای حمام روغن اینرسی، فیلترهای هوای خشک کاغذی، فیلترهای هوای المنت فیلتر پلی اورتان و غیره هستند.

درباره انواع فیلتر هوای خشک کاغذی و انواع المنت فیلتر پلی اورتان

امروز فیلتر هوای حمام روغن را معرفی نمیکنیم، زیرا حذف شده است. امروز بر روی فیلتر هوای خشک کاغذی و فیلتر پلی اورتان تمرکز خواهیم کرد. فیلتر هوای المنت

عنصر فیلتر فیلتر هوای خشک کاغذی از کاغذ فیلتر میکرو متخلخل ساخته شده با رزین ساخته شده است. کاغذ فیلتر متخلخل، شل، تاشو، دارای مقاومت مکانیکی و مقاومت در برابر آب خاص، راندمان فیلتراسیون بالا، ساختار ساده، وزن سبک، هزینه کم، نگهداری آسان و سایر مزایا است و پرکاربردترین فیلتر خودرو است. فیلتر هوا.

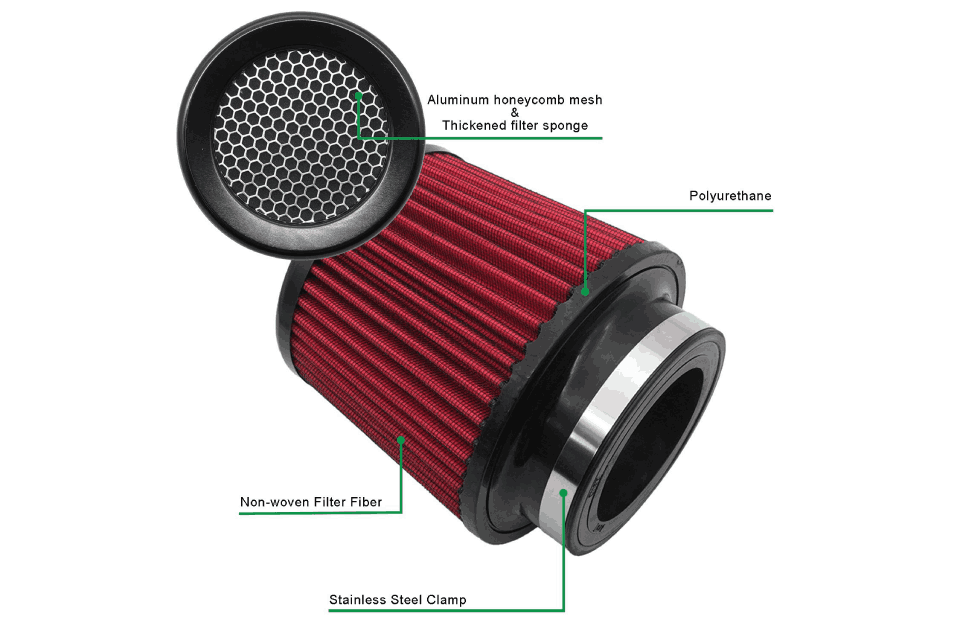

عنصر فیلتر عنصر فیلتر پلی اورتان فیلتر هوا از پلی اورتان نرم، متخلخل و اسفنج مانند با ظرفیت جذب قوی ساخته شده است. این فیلتر هوا مزایای فیلتر هوای خشک کاغذی را دارد، اما استحکام مکانیکی پایینی دارد و به طور گسترده در موتورهای خودرو استفاده میشود.

نصب و استفاده از فیلتر هوا؟

نصب و استفاده

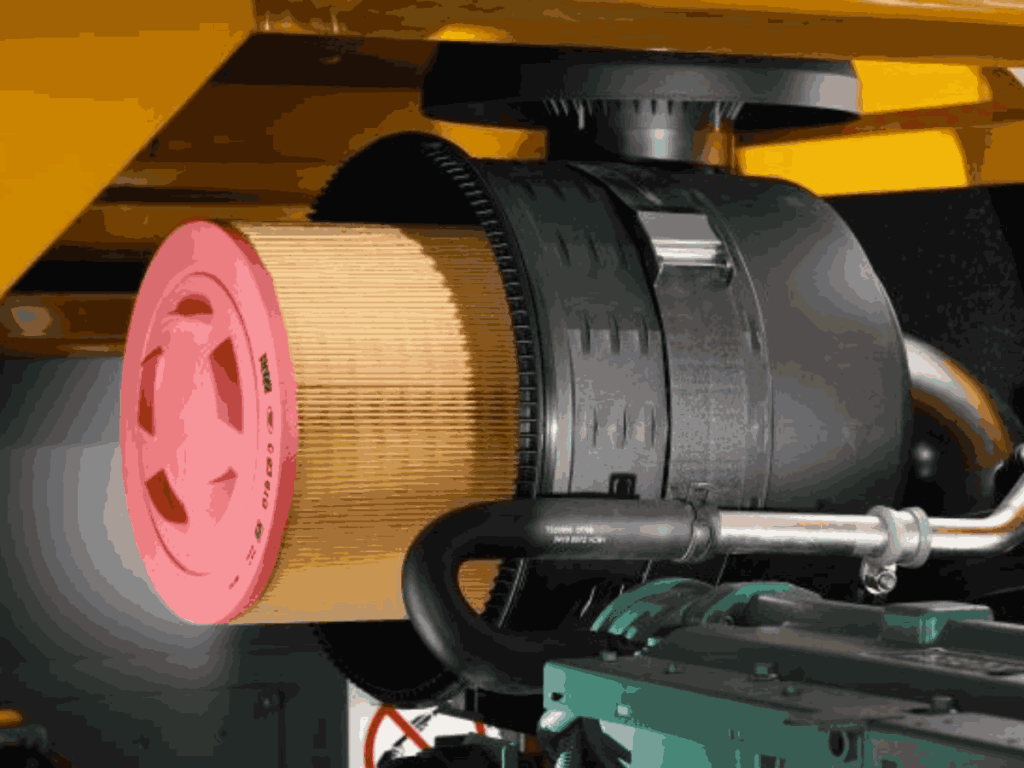

۱. در حین نصب، آیا فیلتر هوا و لوله ورودی موتور توسط فلنج، لوله لاستیکی یا اتصال مستقیم به هم متصل میشوند، باید محکم و قابل اعتماد باشند تا از نشت هوا جلوگیری شود. واشرهای لاستیکی باید در هر دو انتهای المنت فیلتر نصب شوند. مهره بالهای که پوشش فیلتر هوا را محکم میکند، نباید خیلی محکم بسته شود تا از له شدن المنت فیلتر کاغذی جلوگیری شود.

۲. در طول تعمیر و نگهداری، المنت فیلتر کاغذی نباید برای تمیز کردن در روغن قرار داده شود، در غیر این صورت المنت فیلتر کاغذی خراب شده و به راحتی باعث تصادف میشود. در طول تعمیر و نگهداری، فقط میتوان از روش ارتعاش، روش برداشتن برس نرم (برس زدن در امتداد چین و چروکهای آن) یا روش دمیدن معکوس هوای فشرده برای از بین بردن گرد و غبار و آلودگی چسبیده به سطح المنت فیلتر کاغذی استفاده کرد. برای قسمت درشت فیلتر، گرد و غبار باید به موقع از قسمت جمعآوری گرد و غبار، تیغهها و لولههای سیکلون پاک شود. حتی اگر بتوان هر بار با دقت از آن نگهداری کرد، المنت فیلتر کاغذی نمیتواند عملکرد اولیه خود را به طور کامل بازیابی کند و مقاومت ورودی آن افزایش مییابد. بنابراین، معمولاً وقتی المنت فیلتر کاغذی برای چهارمین بار نیاز به نگهداری دارد، باید یک المنت فیلتر جدید جایگزین شود. اگر المنت فیلتر کاغذی شکسته، سوراخ شده یا کاغذ فیلتر و پوشش انتهایی از هم جدا شده باشند، باید فوراً تعویض شود.

3. هنگام استفاده، حتماً از هسته کاغذ جلوگیری کنید فیلتر هوا از خیس شدن در اثر باران، زیرا وقتی هسته کاغذی مقدار زیادی آب جذب میکند، مقاومت ورودی را به شدت افزایش داده و مدت زمان کارکرد را کوتاه میکند. علاوه بر این، فیلتر هوای هسته کاغذی نمیتواند با روغن و آتش تماس پیدا کند.

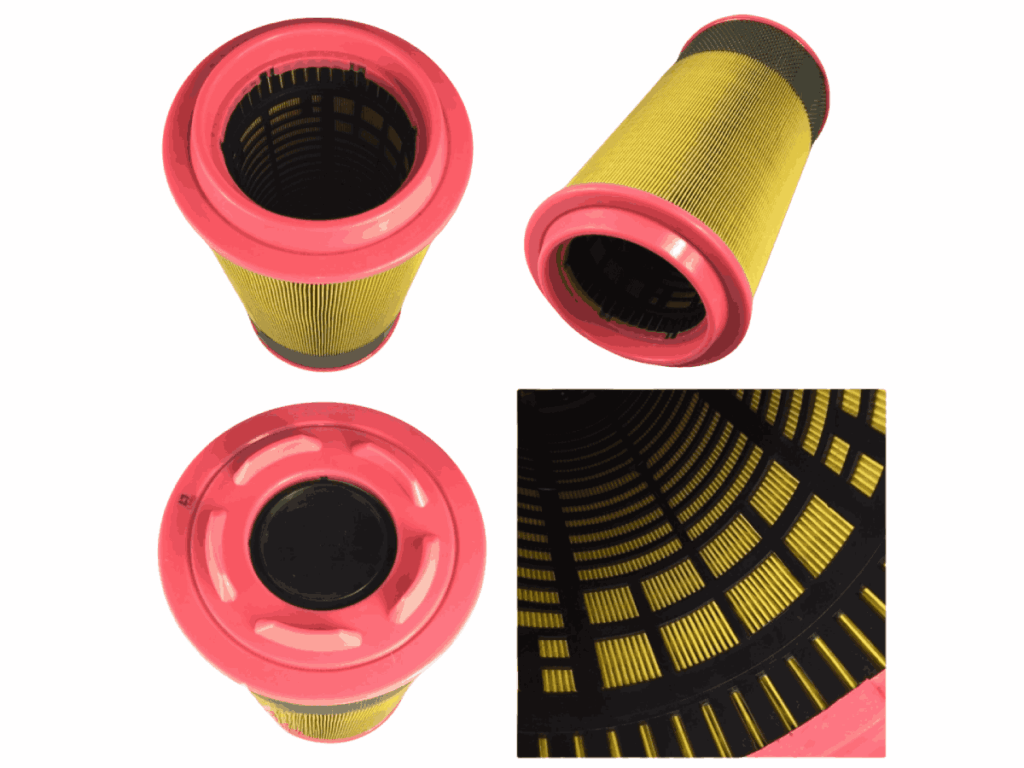

۴. برخی از موتورهای خودرو مجهز به سیکلون هستند فیلترهای هواپوشش پلاستیکی انتهای فیلتر کاغذی، منحرفکننده است. تیغههای روی پوشش باعث چرخش هوا میشوند. ۸۰۱TP3T از گرد و غبار تحت عمل نیروی گریز از مرکز جدا شده و در محفظه گرد و غبار جمع میشود. گرد و غباری که به فیلتر کاغذی میرسد، ۲۰۱TP3T از گرد و غبار استنشاق شده است. راندمان کل فیلتراسیون حدود ۹۹.۷۱TP3T است. بنابراین، هنگام نگهداری فیلتر هوای سیکلون، مراقب باشید که منحرفکننده پلاستیکی روی المنت فیلتر را از دست ندهید.

نگهداری فیلتر هوا

۱. المنت فیلتر جزء اصلی فیلتر است. از مواد مخصوص ساخته شده و یک قطعه آسیبپذیر است. به نگهداری و مراقبت ویژه نیاز دارد.

۲. پس از اینکه فیلتر برای مدت طولانی کار کرد، المنت فیلتر مقداری ناخالصی را جذب کرده است که باعث افزایش فشار و کاهش سرعت جریان میشود. در این زمان، باید به موقع تمیز شود.

۳. هنگام تمیز کردن، حتماً توجه داشته باشید که المنت فیلتر تغییر شکل ندهد یا آسیب نبیند. به طور کلی، عمر مفید المنت فیلتر با توجه به مواد اولیه مختلف مورد استفاده متفاوت است. با این حال، با افزایش زمان استفاده، ناخالصیهای موجود در هوا باعث گرفتگی المنت فیلتر میشوند. بنابراین، به طور کلی، المنت فیلتر PP باید هر سه ماه یکبار تعویض شود؛ المنت فیلتر کربن فعال باید هر شش ماه یکبار تعویض شود؛ و المنت فیلتر الیافی قابل تمیز کردن نیست، بنابراین معمولاً در انتهای پشتی پنبه PP و کربن فعال قرار میگیرد که ایجاد گرفتگی آسان نیست.

هنگام نگهداری فیلتر هوا به چه نکات دیگری باید توجه کنیم؟

کاغذ فیلتر موجود در تجهیزات نیز یکی از عوامل کلیدی است. کاغذ فیلتر در تجهیزات فیلترینگ با کیفیت بالا معمولاً از کاغذ الیاف بسیار ریز پر شده با رزین مصنوعی استفاده میکند که میتواند ناخالصیها را به طور موثر فیلتر کند و ظرفیت ذخیرهسازی آلودگی بالایی دارد. طبق آمار مربوطه، یک اتوبوس با توان خروجی ۱۸۰ کیلووات حدود ۱.۵ کیلوگرم ناخالصی را در ۳۰۰۰۰ کیلومتر رانندگی فیلتر میکند. علاوه بر این، این تجهیزات همچنین الزامات زیادی برای استحکام کاغذ فیلتر دارند. به دلیل جریان هوای زیاد، استحکام کاغذ فیلتر میتواند در برابر جریان هوای قوی مقاومت کند، کارایی فیلتراسیون را تضمین کند و عمر مفید تجهیزات را افزایش دهد.

نتیجهگیری

در مقایسه با فیلتر هوای حمام روغن، هسته کاغذی فیلتر هوا مزایای زیادی دارد: اول، راندمان فیلتراسیون تا ۹۹.۵۱TP3T بالا است و نفوذپذیری گرد و غبار تنها ۰.۱۱TP3T-0.3% است؛ دوم، ساختار جمع و جور است و میتواند در هر جهتی بدون محدود شدن توسط چیدمان قطعات خودرو نصب شود؛ سوم، در حین تعمیر و نگهداری روغن مصرف نمیکند و همچنین میتواند در مصرف نخ پنبهای، نمدی و مواد فلزی صرفهجویی زیادی کند؛ چهارم، وزن کم و هزینه کمی دارد. نکته کلیدی در استفاده از چاه فیلتر هوای هسته کاغذی، حفظ عملکرد آببندی آن و جلوگیری از ورود هوای فیلتر نشده از بایپس به سیلندر موتور است.

نکاتی برای انتخاب فیلتر هوا

با توجه به جنس فیلتر اصلی موتور، انتخاب کنید

برندی با سابقه طولانی در کسب و کار انتخاب کنید

از فروشگاهی با سابقهی طولانی خرید کنید، زیرا کیفیت چیزی است که باعث ماندگاری این برند یا فروشگاه میشود.

نظرات

فیلتر هوای کامینز 4938908: جایگزینی برای موتورهای ISM/QSM 11L

فیلتر هوای کامینز مدل 4938908 یک قطعه جایگزین اصلی است که برای موتورهای دیزلی ISM11 و QSM11 طراحی شده است.

چرا موتورهای دیزلی به فیلتر هوا نیاز دارند؟

موتورهای دیزلی برای اطمینان از عملکرد بهینه و طول عمر خود به فیلترهای هوا متکی هستند و از ورود آلایندههایی مانند گرد و غبار، خاک و سایر ذرات به سیستم احتراق جلوگیری میکنند.

راهنمای سریع انتخاب بهترین فیلتر هوای موتور دیزل

برای موتورهای دیزلی، به ویژه تجهیزات آفرود، انتخاب فیلتر هوای مناسب برای عملکرد قابل اعتماد و محافظت طولانی مدت از موتور ضروری است.

تأثیر فیلترهای هوا برای خودروها و موتورسیکلتهای اصلاحشده چیست؟

نقش فیلتر هوای موتور، فیلتر کردن شن و ماسه و گرد و غبار موجود در هوا، اطمینان از کیفیت هوای ورودی به سیلندر است.

اساس طراحی فیلتر هوای موتور چیست؟

طراحی اساسی فیلتر هوا به گونهای است که به طور مؤثر از ورود انواع گرد و غبار به سیستم ورودی موتور جلوگیری میکند.

- +86 131 5315 0933

- [email protected]

- دوشنبه تا یکشنبه 07:00-21:00