- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

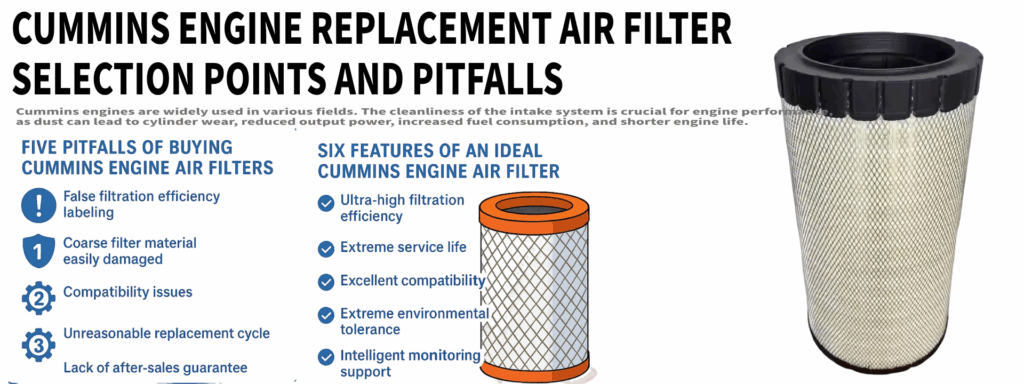

Cummins engine replacement air filter selection points: misunderstanding avoidance strategy and purchase points

1. Introduction: How to choose a replacement air filter with high cost performance and high filtration efficiency?

Cummins engines are widely used in many fields such as trucks, construction machinery, generators, etc. Its performance is closely related to the cleanliness of the intake system. Diesel engines need to inhale 15,000 liters of air for every liter of fuel burned. When the filtration efficiency of the air filter is insufficient, dust will enter the engine, causing cylinder wear, reduced output power, increased fuel consumption, and further shortening the engine life.

There are many brands of air filters on the market. How to choose a replacement air filter with high cost performance and high filtration efficiency?

This article will focus on three to five related topics and conduct a detailed analysis from the aspects of misunderstanding avoidance guide, ideal air filter standards, and issues to pay attention to when purchasing.

2. Five major pitfalls of buying Cummings engine air filters

1 Compatibility issues

Common mistakes: If you buy a non-original air filter, air leakage will occur due to mismatched sizes, and unfiltered air will flow into the engine.

Method: (Original part number AF25708M) Be sure to make a perfect match.

2. Unreasonable replacement cycle

Low-quality filter elements need to be replaced every mile, and maintenance costs increase.

High-quality filter elements, etc., have a service life twice that of traditional filter elements and reduce the frequency of replacement.

3. Lack of after-sales guarantee

Risk: Some brands do not have any consultation on counterfeit and shoddy products, and you may buy recycled or counterfeit products.

Tips to avoid traps: Choose a regular store to ensure quality assurance.

6 features of ideal Cummins engine air filter

Ultra-high filtration efficiency

Nanofiber technology removes 99.99% of micron-sized particles, exceeding 95% of traditional filter elements.

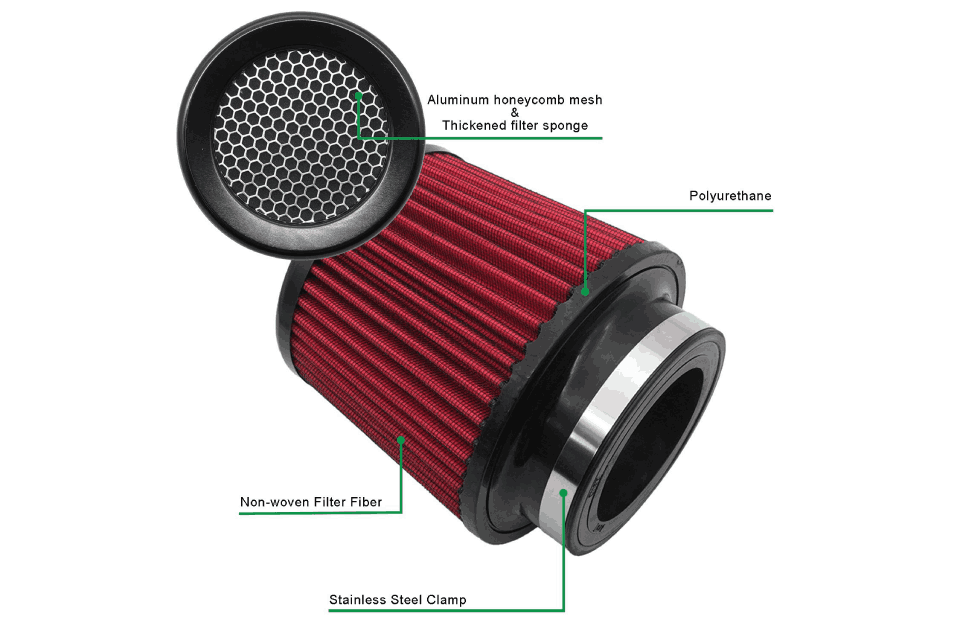

Multi-layer structure: pre-filter layer + high-efficiency filter layer + moisture-proof coating. Suitable for mines, deserts and other environments.

Extreme life

Traditional filter element: replacement kilometers.

High-quality filter element, etc.: more than 30,000 kilometers. Reduce maintenance costs.

4.Excellent compatibility

Unique specifications: ensure airtightness and prevent unfiltered air from penetrating (AF25708M for ISX15)

Extreme environment tolerance

High temperature resistance: 120 degrees Celsius (desert environment).

High humidity resistance: prevent mold growth (tropical rainforest area).

5. Intelligent monitoring support

Some high-level filter elements are integrated with differential pressure sensors to tell you when to replace them to prevent replacement too late or too late.

Environmentally friendly and recyclable

Washable filter elements, such as some synthetic fiber filter elements, reduce waste.

The major problems in purchasing Cummins engine air filters

1. The market is flooded with counterfeit goods

Identification method:

2:Purchase channel: regular dealers or factories

Balance between performance and cost

3:Low-cost trap: Some factories sacrifice filtration efficiency in order to reduce costs, and long-term maintenance will increase engine maintenance costs.

4:Reasonable budget: High-quality air filters are 30% to 50% more expensive than ordinary filters, but will reduce fuel economy by 3-5%.

Adapt to specific working conditions

5:Mines/deserts: dust and high temperature filter elements are required.

Extremely cold areas: The filter element must have strong anti-condensation ability to prevent ice formation, which requires the filter element to undergo special treatment during the production process.

3. Extended content: Four main topics

How to determine the replacement cycle of the air filter?

General recommendation: every 15,000 kilometers or 500 hours (either).

Intelligent monitoring: Some models are equipped with an air filter blockage alarm device, which can be replaced as needed.

Can the air filter be cleaned and recycled?

Filter element: Paper filters cannot be cleaned or replaced.

Synthetic fiber filter: Use a low-pressure air gun to clean.

Impact of air filter on fuel consumption

Filter element stains and blockage: Increase intake resistance and increase fuel consumption by 5-10%.

High-quality filter element: Optimize intake efficiency and reduce fuel consumption by 1%.

4. Classification of regenerated air filters

Appearance inspection: Is there any glue residue at the end of the filter paper? Are there any creases?

Weight comparison: Coarse filter elements are usually lighter.

Conclusion:Procurement suggestions

Give priority to genuine or international brands, such as Boardwide, fleetguard, man+hame, etc.

Check the part number to make sure it is correct.

Choose according to the environment (nanofiber filter elements can be used in high dust environments).

Please pay attention to after-sales service (warranty rules, exchange guide).

Core value

✅ Overcome industry problems (anti-counterfeiting, filtration efficiency, adaptability).

✅ Provide practical solutions (how to identify high-quality filter elements).

✅ Suitable for various working environments (mines, extreme cold, high humidity).

✅ Intelligent monitoring, environmentally friendly filters.

Comments

这是测试文本,单击 “编辑” 按钮更改此文本。

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Learn how to select and replace air filters for CAT 3500 series diesel and gas gensets to protect engines, reduce downtime, and ensure reliable long-term operation.

Why Do Diesel Engines Need Air Filter

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00