- +86 131 5315 0933

- [email protected]

- Jinan Fuxing Industrial Park

Air Filtration in High-Performance and Modified Vehicles: A Technical Deep Dive

1. Introduction: The Critical Role of Air Filtration in Modified Powertrains

In the realm of high-performance and modified cars, every subsystem is pushed beyond its factory style criteria. The air consumption system, and particularly the air filter, is no exception. While frequently viewed simply as a barrier to avoid particles from going into the engine, in a modified powertrain, the air filter becomes a vital component influencing not only engine longevity however also peak efficiency, throttle reaction, and even the calibration of intricate engine management systems. Cars running beyond factory specs, whether through forced induction, increased displacement, or aggressive tuning, need considerably higher air flow rates than their stock counterparts. This increased demand develops an unique challenge for the air filtration system: how to provide the engine with the maximum possible volume of tidy air while simultaneously making sure that hazardous particle matter is efficiently avoided from entering the combustion chamber and triggering sped up wear or damage. The interconnected nature of air filter residential or commercial properties– manufacturer’s advised air flow, air flow resistance, efficiency/arrestance, and dust-holding capability– suggests that optimizing one frequently requires compromises in another, a core conflict that defines the engineering challenge in this space. Understanding this delicate balance is vital for any expert or lover seeking to optimize the capacity of a customized lorry while securing its internal components.

2. The Fundamental Trade-off: Maximizing Airflow While Ensuring Engine Protection

The main engineering obstacle in performance air purification depends on the intrinsic conflict in between taking full advantage of air flow for power and keeping enough filtering efficiency to safeguard the engine. An internal combustion engine requires an exact mix of fuel and air to operate effectively and produce power. The more air that can be drawn into the cylinders, the more fuel can be burned, leading to increased power output. However, the air drawn into the engine is rarely clean; it consists of various particle contaminants, from fine dust and sand to larger debris. These particles, if allowed to enter the engine, can cause considerable damage, consisting of scoring cylinder walls, using piston rings, and damaging valve seats.

An air filter functions by developing a porous barrier that enables air to travel through while trapping these damaging particles. The structure and material of the filter media identify its ability to perform this function. A filter created for optimum air flow will usually have a less limiting structure, indicating larger pores or less thick product. While this allows air to stream more freely, it likewise decreases the filter’s ability to record smaller particles. On the other hand, a filter developed for high purification efficiency will have a denser structure with smaller sized pores, effectively trapping even very fine particles. However, this denser structure naturally limits air flow, developing a pressure drop across the filter. This pressure drop reduces the amount of air that can get in the engine, straight affecting performance.

The relationship between resistance (pressure drop) and flow differs with filter type and media. For some material and most metal filters, resistance increases as the square of the velocity. For laminar airflow through HEPA filters, resistance is almost proportional to speed. For a lot of air conditioning filters, when velocity increases, resistance increases greatly with a power between 1.3 and 1.8. This non-linear relationship suggests that small increases in air flow demand can lead to disproportionately larger increases in pressure drop, worsening the trade-off in high-performance applications.

Additionally, filter effectiveness is not fixed; it generally increases as the filter loads with particle. As dust accumulates on the filter media, it forms a “dust cake” that can enhance the capture of smaller particles. However, this loading also increases airflow resistance. If loaded beyond the manufacturer’s recommendation, effectiveness can decline rapidly as agglomerated particles may be dislodged and pulled into the consumption. Minimizing media air velocity, often accomplished by increasing the filter’s surface area through pleating or bigger filter size, can increase dust-holding capability for the very same final resistance. Media compression, such as at the folds in V-form filters, can minimize dust holding capacity.

For that reason, the fundamental compromise is a vibrant interplay in between filter style, material properties, airflow velocity, and dust loading. Attaining high performance needs decreasing pressure drop, which frequently indicates compromising some degree of filtering effectiveness, while securing the engine requires high effectiveness, which undoubtedly restricts airflow. The objective of efficiency air filter style is to find the optimum balance for a given application, optimizing the air mass circulation rate while guaranteeing that the size and amount of particles going into the engine stay below vital thresholds for accelerated wear.

As a result, the basic trade-off is a vibrant interplay between filter layout, product residential properties, airflow velocity, and dust loading. Achieving high performance needs lessening pressure decline, which usually means sacrificing some level of purification effectiveness, while shielding the engine requires high efficiency, which certainly restricts air flow. The objective of performance air filter layout is to locate the optimal balance for a provided application, making the most of the air mass circulation rate while making certain that the dimension and amount of bits entering the engine remain listed below vital thresholds for accelerated wear.

Why Marine Filtration is Essential: Challenges and Repercussions

The marine environment’s obstacles require robust filtering:

Salt Spray & Aerosols: Highly corrosive, causing sped up deterioration on parts (engines, electronic gadgets) and fouling filters/heat exchangers.

High Humidity: Increases rust rates and promotes microbial advancement (bacteria, mold) in systems.

Vibration: Can damage filters and properties, and remove taped particles.

Diverse Contaminants: Consists of dust, oil mist, exhaust, and biological representatives.

Consequences of bad filtering are extreme:

Accelerated Devices Wear: Abrasive particles damage engines and equipment.

Increased Upkeep & Downtime: Regular repairs and decreased life span lead to greater expenses and operational disturbance.

Health Threats: Poor air quality impacts crew/passenger health.

Non-Compliance: Failure to meet guidelines (e.g., IMO MARPOL Annex VI) on emissions and air quality.

3. Quantifying Performance and Protection: Airflow Measurement and Filtration Standards

Measuring the efficiency and protective abilities of air filters is vital for comparing different styles and guaranteeing they satisfy the demands of high-performance applications. This includes standard methods for determining air movement and purification effectiveness.

Airflow Measurement:

Air movement is commonly determined in Cubic Feet per Minute (CFM) or cubic meters per hour (m TWO/ h). Nevertheless, merely specifying a CFM value for a filter wants without defining the pressure drop at which that flow rate was accomplished. A more interesting metric is the connection in between airflow and pressure decrease throughout the filter element and the whole intake system. Pressure decline, usually measured in inches of water (IN H ₂ O) or Pascals (Pa), represents the resistance to airflow. A lower stress drop at a provided air movement rate suggests a much more effective, much less limiting filter or intake system.

The pressure drop in an air induction system is not entirely as a result of the filter aspect. It also includes contributions from the air inlet, filter housing, and mass flow sensing unit. Experiments have shown that at nominal engine flow prices, a normal filter housing can add around 1.75 kPa of stress decline, and a mass flow sensor around 1.50 kPa. A clean panel-type filter element might only add 0.22 kPa, while conelike filters can have even reduced stress drops. However, as the filter lots with dirt throughout procedure, the filter element comes to be the major resource of stress loss, with terminal stress decline for dust-loaded components usually ranging from 2.5 to 5.0 kPa.

Filtration Standards:

The primary requirement for testing air filters for interior burning engines and compressors is ISO 5011 (formerly SAE J726). This common gives an exact protocol for examining filtration efficiency, air flow limitation throughout dirt loading, and total dust holding ability under regulated problems.

Secret measurements under ISO 5011 include:

Airflow Restriction/Pressure Drop: Measured in IN H ₂ O or kPa versus air movement in CFM or m FOUR/ h. This is gauged at different circulation rates, normally around 50%, 75%, 100%, 125%, and 150% of the ranked air flow. The first constraint of a clean filter and the terminal restriction (the factor at which the examination is ended, frequently defined as an increase of 10 IN H ₂ O over the preliminary restriction) are crucial information factors.

Dust Collection Efficiency:

Evaluated by feeding a recognized quantity of standard examination dirt (such as ISO Coarse Test Dust or ISO Fine Test Dust) into the filter at a consistent price and airflow] An absolute filter put downstream captures any dirt that passes through. The rise in weight of the absolute filter is used to determine the filter component’s performance. Total performance is determined from the total dirt kept. Collective performance, typically the only number advertised in auto applications, includes any type of loading and dirt infiltration measured throughout a first performance test.

The efficiency is determined making use of the formula:

where A is the mass boost of the upstream outright filter and B is the mass boost of the downstream absolute filter.

Dust Holding Capacity:

Measured by the difference between the weight of the filter before and after the examination. This shows just how much dirt the filter can hold prior to getting to the terminal constraint.

ISO 5011 aims for reproducibility, enabling contrast of filter tests executed in different locations. Nevertheless, it has constraints in forecasting real-world efficiency. The procedure was not established to recognize how an air filter will execute in an automobile throughout operation. It makes use of taken care of airflow and is frequently conducted with the filter in a “test real estate,” which differs from actual vehicle use where operating conditions, air flow, and dirt feed rates are variable. Installment orientation and intake system geometry can additionally influence performance compared to bench tests.

Various other relevant requirements and screening techniques exist. The MERV (Minimum Efficiency Reporting Value) score, established by ASHRAE, is typically utilized for HVAC filters yet is occasionally referenced for vehicle filters. It shows a filter’s efficacy in eliminating particles between 0.3 and 10 microns. Higher MERV ratings mean far better capture of smaller sized particles yet can decrease airflow. For high-performance filters, the beta proportion (identified by ISO 16889) contrasts the variety of upstream fragments to downstream particles of an offered dimension. Different examination approaches include the Absolute Airflow Test, DOP and PAO screening (for HEPA/ULPA filters), Sodium Flame Test, and Oil Thread Leak Test.

It is vital to keep in mind that filtering measurements are only meaningful if examination variables (dust grade, air movement rate, terminal examination pressure) are disclosed. Some producers might evaluate at really reduced CFM to artificially pump up efficiency numbers. Credible efficiency filter producers, like K&N and S&B Filters, conduct comprehensive in-house screening, frequently making use of both standard test components and actual OEM air boxes to much better mimic real-world conditions.

4. Application range of high-performance air filters and intake systems

High-performance air purification systems for custom cars include a variety of filter types, materials, and overall intake system styles, each with its own unique characteristics and applications.

For example, plate filters: These are usually direct replacements for the original air filter element and can be installed in the existing intake box. High-efficiency plate filters usually use different filter media than the original paper filter to enhance air flow while maintaining or improving filtration. While retaining the design of the original intake system, it helps meet emission standards and avoid MAF sensor issues.

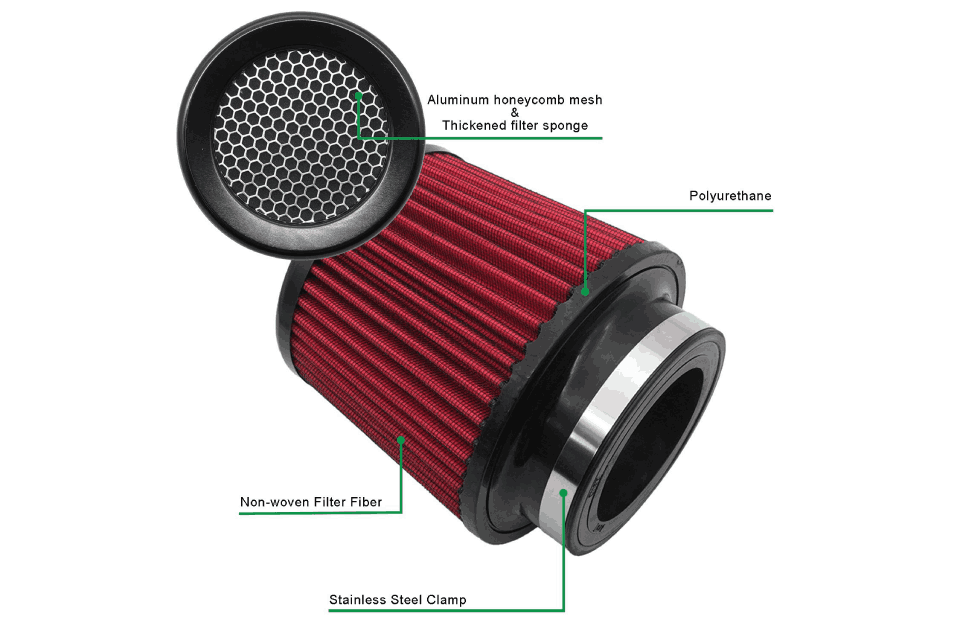

Conical filters: These filters are conical or round and are often used in aftermarket intake systems. Compared with many plate filters, they are designed with a larger surface area, which may increase air flow.

Common filter materials: Oil-impregnated cotton gauze: This type of filter promoted by brands such as K&N and BMC uses multiple layers of cotton gauze that has been specially impregnated with oil. Oil-soaked cotton helps capture fine particles, while the relatively loose weave of the cotton yarn allows for high airflow. These filters are recyclable and are typically cleaned and re-oiled every 10,000 to 15,000 miles. However, over-oiling can contaminate and damage the mass air flow sensor (MAF), so we recommend that customers replace their filters regularly, replacing the original filter with our aftermarket filters, which can be directly installed and get high-efficiency filtration while saving 40-60% of the original price.

Dry Synthetic Fiber: These filters use synthetic fibers (usually multiple layers) to achieve purification without the use of oil. Dust is usually blown off with compressed air or cleaned with a mild detergent. Dry synthetic fiber filters usually have less airflow than oiled cotton filters, but have high purification efficiency, sometimes with impurity capture rates as high as 99%. They usually have longer cleaning intervals of 15,000 to 30,000 miles. aFe POWER’s Pro DRY S filter is an example of a three-layer synthetic media.

Nanofiber Technology: An emerging innovation integrates a nanofiber layer onto standard filter media. These nanofibers are typically produced through electrospinning technology and can significantly improve filtration efficiency, capturing particles as small as 0.1 microns with high efficiency (up to 99.99%) while maintaining low flow restriction. They have smaller pores and larger surface areas, which mechanically enhance particle capture. Nanofibers can be made from a variety of materials, such as cellulose, nylon, or polyester. Filters with nanofiber technology are significantly more expensive than other filters, but they will last longer than other filters.

Types of Performance Air Intake Systems:

A cold air intake system is an area where the air filter is routed to the outside of the engine compartment, such as behind the bumper or inside the fenders, to draw in cooler, denser ambient air. Cold air contains more oxygen per unit volume, which improves combustion efficiency and may increase power. Cold air intake systems typically use larger diameter ducting and either a heat shield or a closed air box to isolate the filter from engine heat. Longer, more complex intake paths can sometimes cause airflow restriction or turbulence if not designed properly.

Short Stroke Intake Systems (SRIs) mount the air filter directly to the throttle body or mass air flow sensor in the engine compartment. This allows for a shorter, smoother intake path than the stock system or cold air intake system, resulting in improved throttle response. However, the filter is exposed to the hot air in the engine compartment, causing an increase in intake air temperature (IAT). Some SRI (Throttle Restriction) units use a heat shield to mitigate this effect.

Our modified car application notes on filter selection

The choice of filter material and intake system design depends largely on the modification and intended use of the vehicle:

Naturally aspirated engine vs. supercharged engine: Supercharged engines are generally less sensitive to intake restrictions than naturally aspirated engines. However, the pressure drop before the compressor in the supercharged system will negatively affect the efficiency of the compressor, resulting in higher outlet temperatures and reduced overall engine efficiency. Naturally aspirated engines will experience increased pumping losses when intake restrictions increase, directly reducing power and efficiency. One study showed that the power loss of a naturally aspirated engine equipped with a throttle filter is twice that of a supercharged engine.

Track and street racing in terms of use environment: Track racing may prioritize maximum airflow and peak power, so there may be slight compromises in filtration efficiency or increased noise. Street racing generally requires a balance between performance, drivability, emissions compliance and reasonable noise levels.

Modified cars have requirements for the use environment of air filters. Vehicles driving in dusty or harsh environments require filters with higher dust holding capacity and higher filtration efficiency, even if this means that peak airflow will be slightly reduced. In demanding applications such as military vehicles, two-stage air filters are used to handle large amounts of mineral dust.

The design principles of high-performance air intake systems involve a fundamental trade-off between reducing intake air temperatures and reducing airflow restrictions. Tube length and diameter affect resonance effects and airflow velocity, which in turn affect torque output and throttle response. Computational fluid dynamics (CFD) is a valuable tool used by manufacturers to optimize intake designs for minimal pressure drop and optimal flow characteristics. The design of the intake manifold also plays a major role in overall system performance.

Conclusion

High-performance and modified vehicle air filters are the key to optimizing engine performance and protection. By balancing air flow and filtration efficiency, the filter design ensures that the engine is protected from particulate matter while meeting power requirements. Technologies such as cold air intake and short-stroke intake systems, oil-impregnated cotton yarn, dry synthetic fibers and nanofibers provide diverse options for different application scenarios. ISO 5011 standard testing provides a reliable basis for evaluating filter performance, and the correct selection of filters and intake systems requires customized considerations based on the degree of vehicle modification, operating environment and performance goals. Ultimately, an optimized air filtration system not only improves power output, but also extends engine life, providing modified car enthusiasts and professionals with a perfect combination of performance and reliability.

Comments

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How to Maintain CAT 3500 Series Diesel & Gas Gensets: Air Filter Selection & Replacement Guide

Learn how to select and replace air filters for CAT 3500 series diesel and gas gensets to protect engines, reduce downtime, and ensure reliable long-term operation.

Why Do Diesel Engines Need Air Filter

Diesel engines rely on air filters to ensure their optimal performance and longevity by preventing contaminants such as dust, dirt, and other particulates from entering the combustion system

Fast Choosing the Best Diesel Engine Air Filter Guide

For diesel engines especially the off-road equipment, selecting the right air filter is essential for reliable performance and long term engine protection

What is the effect of air filters for modified cars and motorcycles?

The role of the engine air filter is to filter the sand and dust in the air, ensure the quality of the air entering the cylinder

What is the basis of engine air filter design?

The basic design of air filter is to effectively prevent all kinds of dust from entering the engine’s intake system

- +86 131 5315 0933

- [email protected]

- Mon-Sun 07:00-21:00